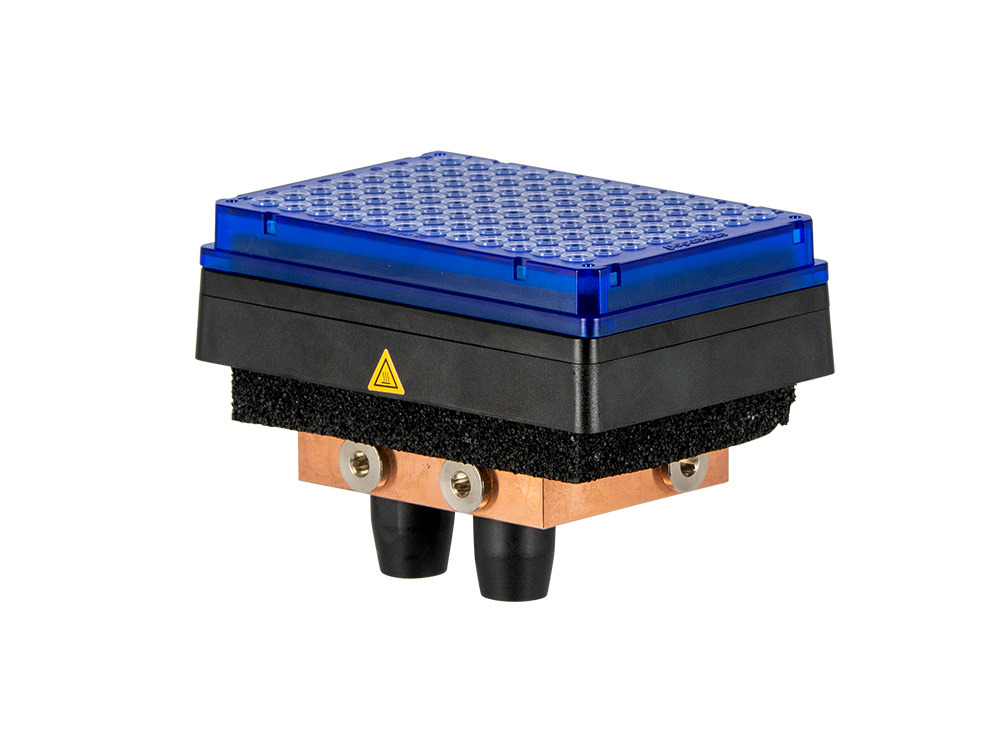

CPLC – Cold Plate Liquid Cooled Heater/Cooler

Heat, cool or freeze your samples, not your deck

Heat and cool samples precisely, without fear of contamination. Our Peltier-based heater/cooler uses liquid cooling for near-silent operation without generating waste heat or air on deck.On-deck heater/coolers can be problematic when working without on-deck air-conditioning. Labs report problems with on-deck waste heat that increases the ambient temperature of the deck, air movement from fans increases the risk of sample cross-contamination, and there’s excessive noise when many devices work together. Cold plate liquid cooling moves heat dispersal off deck and can solve those problems.

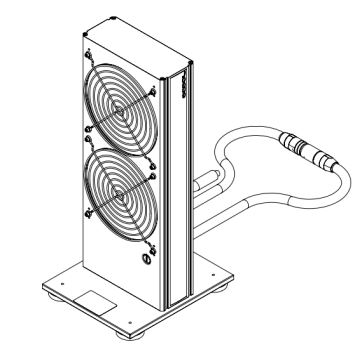

OFF DECK LIQUID COOLING

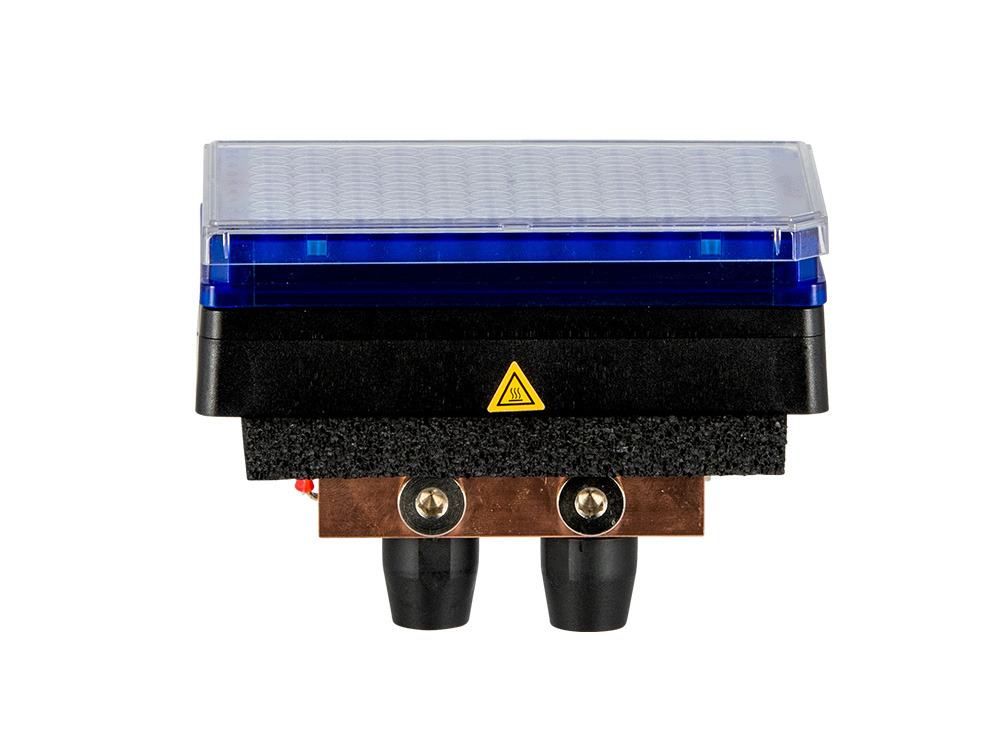

The CPLC replaces the usual on-deck heat sink/fan combination with liquid heat exchangers and transfer heat to the environment via a heat exchanger outside the deck. For fast heating and cooling steps that require high precision there’s less risk of disturbance or contamination from waste heat generation or air movement from fans.

ON DECK ACCURATE HEATING & COOLING

The CPLC uses a two Peltier heating/cooling capability. In a multi-unit setup, the Peltiers enable individual heating/cooling settings using just the one heat exchanger. The heat exchanger can be a passive ambient temperature unit, or an active cooler in case of very high/low temperature setting, including sub-zero.

Temperature range 4° C to 105° C, uniformity of 0.5 K, accuracy of 0.3 K.

EASY to INTEGRATE

The CPLC occupies only one ANSI/SLAS plate position on deck. It comes with an API ready to integrate with your automated liquid handling workstation. Control your CPLC with the separate off-deck Inheco Single TEC Control unit (STC) which further minimizes deck space and reduces noise and temperature. Or choose the Inheco Multi TEC Control (MTC) unit to control up to six devices in parallel when using several Inheco products on your deck.

ADAPTABLE

You can use your preferred disposable with the CPLC, including vials and reservoirs - we offer over 200 adapters, manufactured inhouse to ensure a perfect fit to the geometry of the disposable item, or can tailor an adapter to fit your needs.

RELIABLE and SUPPORTED

Every Inheco device is designed, engineered and made in Germany and undergoes rigorous quality control before delivery. It comes with a global two-year warranty and full customer service including remote support, diagnostic and servicing options that focusses on minimizing operational downtime.

Get a Quote